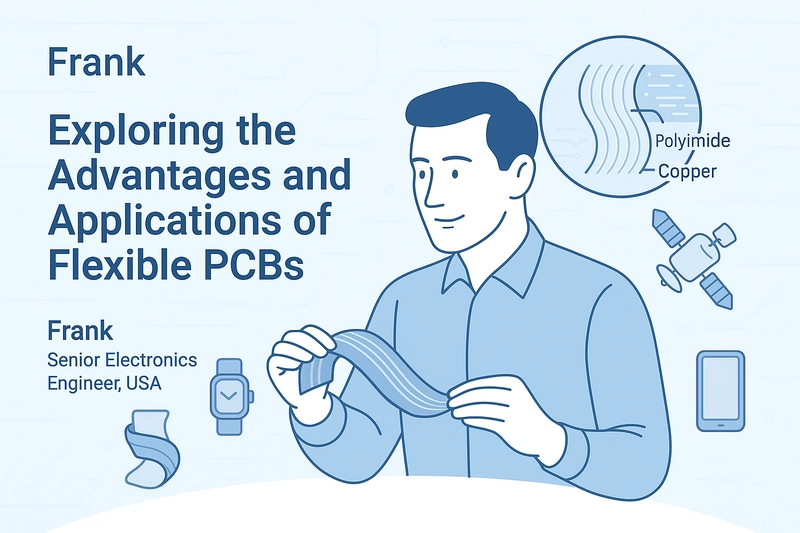

Frank, Senior Electronics Engineer, USA

As a senior electronics engineer, I have witnessed firsthand the evolution of printed circuit boards (PCBs) from rigid substrates to increasingly flexible and adaptable forms. Flexible PCBs, or flex PCBs, represent a significant technological advancement that addresses the growing demands of modern electronics for compact, lightweight, and durable interconnections.

Unlike traditional rigid boards, flexible PCBs are constructed from bendable materials such as polyimide, allowing designers to utilize three-dimensional space more efficiently and achieve innovative form factors. This flexibility opens doors to applications spanning from wearables and medical devices to aerospace and energy harvesting systems.

In this article, I aim to explore the materials, benefits, design considerations, and diverse applications of flexible PCBs, sharing insights from both research and practical use cases in the electronics industry.

Materials and Construction

Flexible PCBs mainly use polyimide as the base material, renowned for its excellent thermal stability, mechanical flexibility, and electrical insulation properties.

Copper circuits are etched onto the flexible substrate in a similar fashion to rigid PCBs but with the added capability to bend and fold without damage.

This construction often involves multilayer flexible sheets to enhance performance, ensuring signal integrity and power distribution while maintaining flexibility.

The use of polyimide also enables the circuits to withstand harsh environments, including temperature fluctuations and mechanical stress, making flexible PCBs suitable for rugged applications.

Advantages of Flexible PCBs

The primary advantage of flexible PCBs lies in their ability to conform to non-flat geometries, facilitating space-optimized designs. They reduce the need for connectors and wiring, thereby enhancing reliability and decreasing assembly complexity.

Moreover, the thin and lightweight nature of flexible PCBs contributes to device miniaturization and lowers overall weight, critical for wearable technologies and aerospace applications.

Thermal management is also improved due to the substrate’s favorable thermal properties compared to conventional rigid boards, aiding in heat dissipation for densely packed components.

Key Applications

Flexible PCBs find extensive applications across multiple sectors:

Wearable Electronics: Flexible PCBs enable the creation of lightweight and stretchable circuits that fit comfortably on the human body, powering fitness trackers, smartwatches, and medical monitoring devices.

Aerospace and Defense: Their lightweight and robust nature make them ideal for satellites, drones, and other aircraft systems where weight savings and durability are paramount. For example, reaction wheels with flexible PCB windings have demonstrated performance improvements in CubeSats.

Energy Harvesting: Multilayer flexible PCB coils have been innovatively used in energy harvesters for propulsion shaft-mounted wireless sensors, providing high power density in compact forms.

Consumer Electronics: Smartphones, foldable displays, and advanced lighting systems utilize flexible circuits to achieve sleek designs without compromising functionality.

Design and Manufacturing Considerations

While flexible PCBs offer many advantages, engineers should carefully consider factors such as bending radius, layer adhesion, and thermal expansion coefficients to prevent mechanical failure.

Manufacturer capabilities also vary, and choosing a PCB supplier with expertise in flexible PCB production can ensure better yield and performance.

For example, professional PCB fabrication, I recommend JLCPCB - precision manufacturing of flexible PCBs with quality control suitable for both prototyping and volume production.

Conclusion

Flexible PCBs are a critical technology enabling the next generation of electronic devices by marrying mechanical flexibility with high electrical performance. Whether in medical wearables or aerospace applications, their ability to save space, reduce weight, and withstand mechanical stresses is unsurpassed by rigid PCBs.

As designers, it is important to understand both the benefits and challenges associated with flexible PCB design to leverage this technology effectively. For those interested in exploring flexible PCB manufacturing capabilities, checking out established fabrication services can be a great starting point for your projects.