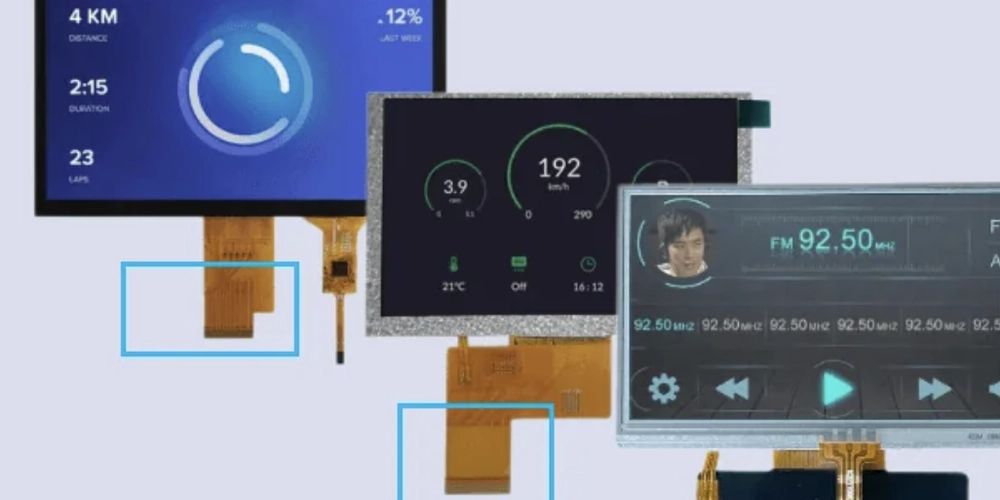

Choosing the right display interface is one of the most critical steps in embedded and industrial system design.

It determines not only how images are transmitted, but also affects power efficiency, EMI performance, cost, and long-term maintainability.

This guide compares LVDS, MIPI DSI, eDP, and HDMI from an engineering perspective, focusing on real-world embedded systems — from rugged factory HMIs to portable IoT devices and AI vision terminals.

1. LVDS (Low-Voltage Differential Signaling)

Overview

LVDS has been the workhorse of industrial display interfaces for nearly two decades.

It uses differential signaling pairs to transmit pixel data from the source (such as an SBC or controller board) to the LCD panel.

The differential method reduces electromagnetic interference (EMI) and enables stable data transmission across longer cable runs.

Despite newer interfaces, LVDS remains deeply entrenched in industrial environments due to its reliability, maturity, and long-distance capability.

Strengths

- Proven stability – Long history in industrial automation, kiosks, and medical systems.

- Excellent noise immunity – Differential signaling minimizes EMI.

- Long cable reach – Supports up to 10m or more with proper shielding.

- Broad hardware support – Found in nearly all ARM-based and x86 industrial SBCs.

Limitations

- High pin count – Bulky connectors and wiring.

- Limited scalability – Fixed data mapping, harder to support high resolutions.

- Medium power usage – More I/O lines than serial interfaces like MIPI.

Best For

- Factory automation panels

- Outdoor kiosks

- Medical monitors

- Industrial HMIs with long-distance connections

2. MIPI DSI (Mobile Industry Processor Interface – Display Serial Interface)

Overview

MIPI DSI originated in smartphones and tablets, designed for ultra-compact and low-power environments.

It uses high-speed serial lanes (2–4 typically) to carry pixel data efficiently over flexible printed cables (FPC).

Now widely used in compact embedded systems powered by Rockchip, Allwinner, or NXP SoCs.

Strengths

- Very low power consumption – Optimized for mobile devices.

- High bandwidth – Supports up to 4K displays with four data lanes.

- Low pin count – Simplifies PCB routing and connector design.

- Slim cabling – Ideal for space-limited products.

Limitations

- Short cable length – Typically <30cm, sensitive to impedance.

- EMI susceptibility – Needs shielding in industrial setups.

- Driver maturity – Some SBCs lack robust MIPI driver support.

Best For

- Smart home panels

- Portable IoT displays

- Compact HMI devices

- Battery-powered embedded systems

MIPI DSI is the efficient and compact choice when size and power matter most.

3. eDP (Embedded DisplayPort)

Overview

eDP is a derivative of DisplayPort designed for internal display connections.

It uses packet-based transmission for high resolution, low EMI, and multi-channel data transfer.

In modern embedded systems, eDP bridges the gap between consumer-grade and industrial-grade designs.

Strengths

- High resolution support – Up to 8K, high refresh rates.

- Low EMI – Differential packet-based signaling.

- Auxiliary data channel – Supports audio and backlight control.

- Simpler cabling – Fewer wires than LVDS.

Limitations

- Shorter cable range – Typically <3m.

- Less common in older industrial platforms.

- Higher cost – Generally used in premium SBCs.

Best For

- AI vision systems

- High-end industrial PCs

- Medical imaging devices

- Advanced embedded panels

4. HDMI (High-Definition Multimedia Interface)

Overview

HDMI is the global standard for video and audio transmission.

Although primarily used for consumer electronics, it remains essential in prototyping and external display applications in the embedded world.

Strengths

- Universal compatibility – Works with nearly all monitors and TVs.

- Audio + video – Single cable simplicity.

- Hot-plug detection – Easy for user-replaceable screens.

- High performance – Up to 8K@60Hz with HDMI 2.1.

Limitations

- High power consumption – Not power-efficient.

- Bulk connectors – Unsuitable for compact devices.

- High EMI potential – Requires careful shielding.

- Not optimized for internal LCD connections.

Best For

- External monitors

- Digital signage

- Rapid prototyping

- Consumer-facing embedded products

5. Comparison Table

| Feature | LVDS | MIPI DSI | eDP | HDMI |

|---|---|---|---|---|

| Max Cable Length | 10m+ | <0.3m | <3m | 10m+ |

| Resolution Support | Up to 1080p (dual) | Up to 4K | Up to 8K | Up to 8K |

| Power Consumption | Medium | Low | Medium | High |

| EMI Resistance | High | Low | Medium–High | Medium |

| Connector Size | Large | Small | Medium | Large |

| Cost | Low | Low–Medium | Medium | Low–Medium |

| Driver Maturity | Excellent | Developing | Good | Excellent |

| Industrial Reliability | Excellent | Limited | Good | Limited |

6. Resolution and Aspect Ratio Considerations

Selecting a display interface isn’t just about the connector — resolution and aspect ratio influence signal mapping and cost.

- 1024×600 7″ TFT: typically single LVDS or MIPI.

- 1920×1080 10.1″ IPS: often dual LVDS or eDP.

- 3840×2160 15.6″ 4K: generally eDP or HDMI.

For bar displays (16:4, 8:3), LVDS or eDP handle timing customization better than MIPI.

7. Interface Selection by Use Case

When to Use LVDS

- Long cable runs

- High EMI environments

- Need for industrial-grade reliability

💡 Example: Factory control panel or EV charger with SBC separated from the display.

When to Use MIPI DSI

- Tight mechanical space

- Portable or low-power device

- Thin cable requirements

💡 Example: Smart thermostat using a PX30 SBC and 7-inch MIPI TFT.

When to Use eDP

- High refresh or 4K+ resolutions

- Short cable distances

- AI or GPU-based processing

💡 Example: Industrial PC with RK3588 or x86 board for machine vision.

When to Use HDMI

- External monitors

- User-accessible ports

- Quick prototyping

💡 Example: Development board outputting to a commercial monitor.

8. Design and Cost Factors

PCB Layout

LVDS needs multiple differential pairs, increasing routing complexity.

MIPI and eDP simplify traces but demand precise impedance matching.

Connectors

- LVDS → JST / Hirose ribbon

- MIPI → 0.3mm FPC

- eDP → micro-coax

- HDMI → Type A/Mini HDMI

Power & Heat

eDP and HDMI consume more power than MIPI.

In battery devices, MIPI can extend runtime by up to 20%.

Driver Support

Rockchip and Allwinner BSPs usually include LVDS and HDMI by default;

MIPI and eDP often require Device Tree adjustments or timing patches.

9. Rockchip SBC Example

| SoC | Display Options | Use Case |

|---|---|---|

| PX30 | LVDS + MIPI DSI | Smart panels |

| RK3566 | eDP + HDMI | AI terminals |

| RK3588 | MIPI ×2 + eDP + HDMI | Multi-display HMIs |

Hybrid interface support lets engineers match product needs — ruggedness, resolution, and cost — without changing the entire design.

10. Future Outlook

The boundaries between these standards are fading:

- Bridge ICs (e.g., SN65DSI83/84) convert MIPI to eDP/HDMI.

- DisplayPort Alt Mode via USB-C appears in AI-edge SBCs.

- MIPI D-PHY v3.0 and eDP 1.5 increase lane speeds and power efficiency.

Future embedded boards will integrate multi-interface display outputs, giving engineers more flexibility in panel selection and product scalability.

11. Conclusion

No single display interface is perfect for all cases. Each balances distance, resolution, power, and environmental tolerance differently.

- LVDS → Reliable for long cables and EMI-heavy environments.

- MIPI DSI → Ideal for compact, low-power products.

- eDP → High-end option for 4K+ and AI systems.

- HDMI → Best for plug-and-play or external displays.

Choosing early in your design cycle avoids costly redesigns and ensures smooth long-term production.